CHEVALIER 220-LNSY MULTI-AXIS TURNING & MILLING CNC LATHE

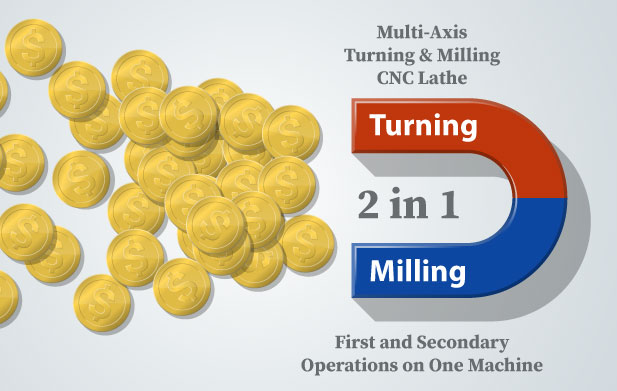

Double the functions, double the money!

The newly designed, multi-functional FNL-220LSY Series multi-axis lathe incorporates many innovative features.

Turning and milling with first and second operations are in one machine. Y-axis travel (±2.17" from the centerline) for off-center milling is the largest range in its class. The series features high-torque live tooling, with full C-axis for the main and sub-spindle. The ability to turn and mill complex parts reduces the amount of operations and handling on one machine as it increases throughput in general. The machine is superior to the competition with a competitive price.

- Sixty-degree, compound Y-axis, slant bed design with roller linear ways.

- German SAUTER, 16-station BMT-45 live turret with maximum 6,000 RPM live tooling speed with all stations live.

- Hydraulic clamping cylinder with a disk break to ensure the rigidity for heavy-duty milling.

- Full C-axis in both spindles with a minimum interpolation of 0.001 degrees.

- FANUC 0i-TF control with FANUC drives and motors plus 10.4" color LCD with a fully conversational Manual Guide i program and 3D simulation.

- Bar-Capacity on main and sub-spindle — 2.55” / 65mm on main spindle and 1.77” / 45mm on sub-spindle.

Standard Accessories — Chip conveyor, parts catcher, oil skimmer, tool presetter, 150psi high-pressure coolant, turning holder package, rotary holders package and more.